LIGHT STAMPING CAPABILITIES INCLUDE BASIC AND INTRICATE DESIGNS MANUFACTURED WITH LOW AND HIGH CARBON STEELS.

Light stampings are typically referred to as flat metal formed parts that use thin gauged materials. However, some light stampings such as washers and spacers do not call for bends in their designs, therefore, they are flat in nature with no forming. The use of thinner materials does not require the need for heavy forming equipment. Light stampings can be found in many applications, but most common uses for light stampings apply when there is a need to connect additional components or help in providing support to an assembly.

Light Stamping Manufacturing

manufactures light stampings using equipment that consists of a variety of bending and forming equipment that is capable of putting bends and forms in a required design

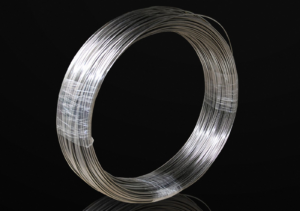

Light Stamping Materials

Materials most commonly use are low carbon, cold rolled steel, and high carbon spring steels ranging from Grade 1050 to 1095, along with Stainless Steels and precious metals such as Brass, Phosphor Bronze, and Beryllium Copper. light stampings with a variety of special finishes or coatings with various heat treating requirements.