A WIDE RANGE OF SIMPLE AND COMPLEX CLIPS & FASTENERS DESIGNS MANUFACTURED USING LOW AND HIGH CARBON STEELS

Clips and Fasteners are most commonly categorized as flat or sheet material that is formed into simple or complicated shapes. Most often, Clips and Fasteners are manufactured using both low and high carbon steels, depending on the application. In some applications, high carbon spring steels are utilized where a spring force is required that cannot be obtained with normal spring forces. When high carbon spring steels are used for manufacturing, it is a standard requirement that the product is heat treated and quenched to a hardness level that allows the product to flex without deforming. Heat treating and oil quenching are commonly used for the hardening process, but an Austemper heat treating process is typically the best practice for eliminating heat treat deformation.

Common Industries for Metal Clips and Fasteners

Metal Clips and Fasteners are found throughout many applications. Here are some common industries where clips and fasteners are used:

- Automotive

- Industrial

- Military

- Construction

- Aerospace

- Appliance

- Marine

- Medical

- Electronics

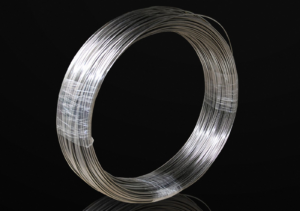

Common Materials for Clips and Fasteners

Steels most commonly used in our process for manufacturing Clips and Fasteners are either low carbon, cold rolled steel (without heat treatment), and high carbon spring steels ranging from Grade 1050 to 1095, along with Stainless Steels and precious metals such as Brass, Phosphor Bronze, and Beryllium Copper. We can supply Clips and Fasteners with a variety of special finishes or coatings to your specification along with various heat treating requirements.

Different Shapes for Clips and Fasteners

Metal Clips and Fasteners can be formed into a wide variety of shapes. Here are some of the common shapes of clips and fasteners:

- U- Clips

- C- Clips

- S- Clips

- D-Spring Clip

- Tubular Clips

- Dart Clips

- Dart-Type Fasteners

- Molding Fasteners

- Flat Spring Clips

- Round Metal Clips