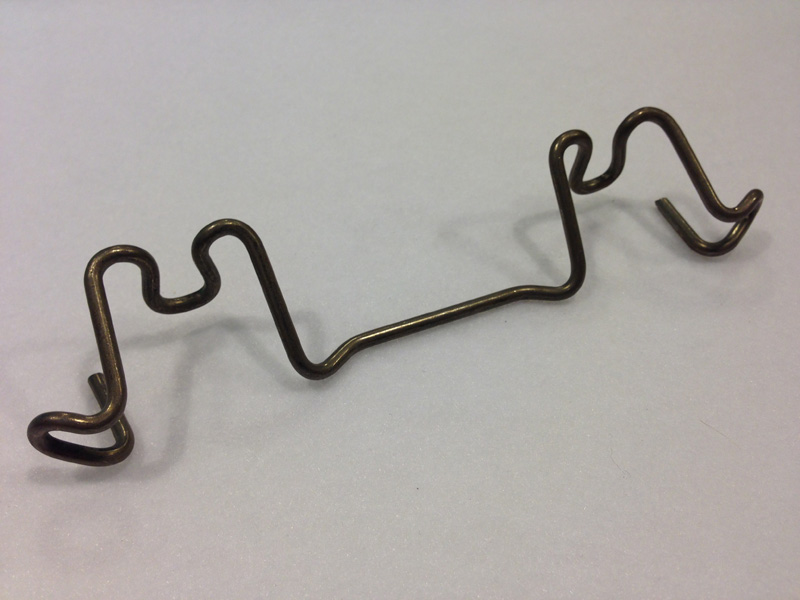

WIRE FORMS MANUFACTURED TO BASIC AND INTRICATE DESIGNS USING LOW AND HIGH CARBON STEELS.

Wire forms are used for many different purposes and have many different bend configurations based on the application. Wire forms can be designed to provide forces in applications where a deflection or torsional force is needed using high carbon spring steel, or where support or structure is necessary using low carbon steel. Typical designs for wire forms include linkages, torsion bars/rods, and wires. Linkages are products that require the need for two or more details to connect and work together to manage forces and movement. A torsion bar/rod is a wire form that provides torsional forces when one or both ends are rotated along the length of the part.

In terms of manufacturing, wire forms are most commonly manufactured from automated presses and hand bending equipment.

Wire Form Applications

While most industries utilize wire forms, there are common applications where wire forms can be found such as:

- Torque rods/bars

- Electrical applications

- Hooks

- Structure support (plastics)

- Connectors

Steels that are most commonly used for manufacturing wire forms are either low carbon cold rolled steel or high carbon spring steels such as Oil Tempered, Chrome Silicon, Music, and Stainless Steel wire.