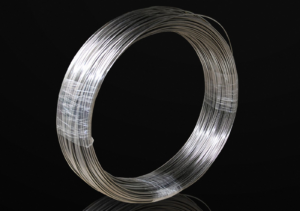

Typically composed of 0.45% to 0.86% carbon, High Carbon Wire is often referred to as carbon tool wire. Hard to cut, weld, or bend, High Carbon Wire becomes slightly stiff and brittle after heat treatment.

Wires made from high carbon steel are widely used in a variety of different applications.

In order to enhance wire performance, carbon can be used as a principal alloy to increase hardness and strength. The effects of elevated carbon proportions include reduced ductility, impact toughness, and weldability.

If these minimized properties can be allowed, high carbon wires can produce remarkable hardness and strength. The production of Sivaco’s high carbon wire is monitored and managed meticulously at all stages to ensure it meets or exceeds ASTM and International standards.

APPLICATION EXAMPLES

- springs

- telecommunication wires

- wire ropes

SPECIFICATIONS

ASTM A679, A228, A227, A648

JIS G3521, G3522

BS 5216, 3592

EN 10270-1, 10264-2

DIN 17223

PHYSICAL AND MECHANICAL PROPERTIES

According to EN,JIS,BS,DIN,GB,ASTM and international standards in all grades and types and/or specific customer requirements