Torsion springs are unique springs that derive their name from their remarkable ability to store and release energy through twisting or rotational motion along their axis. They play an important role in commonplace items like clothespins and clipboards to sophisticated applications within medical equipment and automotive systems.

This article will discuss torsion springs, their common aliases (including rotation, torque, and twist springs), and their diverse applications across a multitude of industries.

What Is a Torsion Spring?

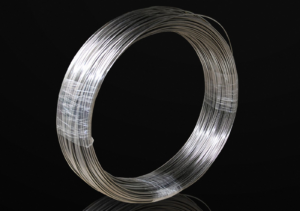

A torsion spring is a mechanical spring designed to store and release rotational energy or torque when twisted around its axis. Despite its name, torsion springs primarily endure bending stress rather than pure torsional forces. These springs consist of coiled wire, with one end affixed to a stationary point and the other end attached to a component that is capable of a degree of movement or rotation. When twisted, torsion springs store potential energy through the coiling process, resisting rotational force. Releasing this force allows the spring to unwind, releasing the stored energy.

Torsion springs find applications in various industries, functioning in situations in which torque is applied from two directions. They come in different configurations, including closed or open coil spacing, based on the specific requirements of the application. Some designs incorporate a slight (open) pitch to reduce friction between adjacent coils and maintain their physical integrity over time. Unlike other spring types, such as compression springs, which work linearly, torsion springs operate rotationally, applying bending stress and resistance. Their ability to store and release energy is governed by Hooke’s Law.

How Do Torsion Springs Work?

Torsion springs function by storing and releasing energy through the application of a twisting or rotational force around their axis. These springs consist of coiled wire, with one end anchored to a fixed point and the other end attached to a rotating (or movable) point or mechanism. When the rotating point is twisted, the spring stores potential energy by coiling tighter, imparting stress on the spring. This twisting motion resists the applied rotational force, with the wire winding around the spring’s axis. The more the spring is twisted, the more energy it stores. Upon release of the rotational force, the torsion spring unwinds, returning to its original position, and in the process, it releases the stored energy. This released energy generates torque and can be used to move or hold mechanical components in place.

Types of Torsion Springs

Torsion springs come in various types, each tailored to specific applications and requirements. Some types of torsion springs are listed below:

Single Torsion Helical Springs

Single torsion helical springs are the most common among all types. A wire is formed into a helix, with its ends extended to create legs. Load is exerted to rotate the spring around its axis. They are suitable for a variety of applications, from simple uses like clipboard clips to more demanding roles in construction and automobile manufacturing.

Double Torsion Helical Springs

These springs are composed of two coils, one left-hand and one right-hand, mirroring each other. Wound from a single length of wire, they feature central legs connected in a 180-degree bend to reduce friction. The coils function in parallel, and the combined torque of each coil equals the spring’s total torque. Double torsion helical springs are ideal for tasks that involve the following actions on rotating loads: rotating, lifting, neutralizing, or centering.

Torsion Bars

These bars are made of elastic and flexible straight bars that can be rotated, or twisted, within their elastic limit. When torque is applied at their ends, they experience shear stress along their axes. These bars are commonly constructed from materials like steel and rubber and are frequently employed in heavy-duty applications.

Torsion Fibers

A torsion fiber is a type of torsion bar, designed for sensitive devices and light-duty applications. Unlike their sturdier counterparts, torsion fibers may require an initial tension to exert a return torque, allowing them to fulfill their precise function. The inherent sensitivity and lightweight nature of torsion fibers make them ideal candidates for applications in which precision and fine-tuned performance are crucial. Torsion fibers are typically crafted from materials such as quartz fibers, silk, or glass.

Spiral Wound Torsion Springs

These springs are engineered from wire coiled into a flat spiral configuration. These springs are characterized by load application at the free end of the spiral while the central end remains fixed. What sets them apart is their unique design, with coils encircling each other rather than stacking, facilitating substantial angular displacements with multiple revolutions.

These springs are prized for applications requiring consistent energy output, as they deliver significant angular displacement with minimal torque variations.

Torsion Spring Applications

Torsion springs find versatile applications across various industries due to their ability to store and release rotational energy effectively. Here are some common applications:

Clothespins and Clipboards

Torsion springs are employed in everyday items. For example, clothespins, which require a firm grip to hold clothing in place, and clipboards, in which they provide the necessary tension to hold papers securely.

Spring-Loaded Hinges

Spring-loaded hinges feature torsion springs inserted through their knuckles, with the legs of the torsion spring attached to rectangular plates. These springs provide a self-closing mechanism for a variety of applications, such as: residential, commercial, automotive, agricultural vehicles, and even garage doors and compartments. When force is applied to the door and then released, the torsion spring helps keep the door securely closed. In some cases, the spring in the hinge can be configured to statically hold the door in an open position.

Clock Spring

Clock springs, also known as main springs, belong to the category of spiral-wound torsion springs. These springs are renowned for providing a consistent force output while accommodating significant angular deflections with minimal variation in torque. Clock springs find application in mechanical watches, in which they store energy when wound by a knob. The stored energy in the clock spring powers the timekeeping mechanisms as it gradually unwinds. Clock springs are also integral components in various timekeeping devices, including: watches, clocks, metronomes, timers, music boxes, and wind-up toys.

Medical Equipment

Torsion springs are utilized in various medical devices and equipment, such as surgical instruments and diagnostic tools. Their precision and reliability are critical in the healthcare field, ensuring that medical equipment functions as intended.

Automotive

Torsion bar suspensions are used in automobiles to support trailing arms when lateral or vertical forces are applied to the wheels. Under such conditions, the torsion bar twists along its axis to prevent deflection in the trailing arms, contributing to the vehicle’s stability and handling.

Clock springs are also used in vehicles, in which they are positioned between the steering wheel and the steering column. They maintain electrical connections to crucial systems like: airbags, horns, and radios, allowing the steering wheel to rotate freely without tangling or damaging electrical wiring. This ensures the safe and uninterrupted operation of these systems while driving.

Door Hinges

Torsion springs are commonly integrated into door hinges, especially in commercial and industrial settings. They assist in the controlled and automatic closing of doors, reducing the effort required to open or close them.

Garage Doors

One of the most well-known applications of torsion springs is in garage doors. Torsion springs counterbalance the weight of the garage door, making it easier to lift and lower. They play a crucial role in the safe and efficient operation of these heavy doors.

What Are Torsion Springs Made Of?

Torsion springs are crafted from a variety of materials, each chosen for specific applications based on their properties. The most common materials used for torsion springs include:

Spring Steels: These steels are renowned for their pliability, high resilience, and strength. They can be extended, compressed, bent, and twisted to their elastic limit and return to their original shape without deformation. Spring steels have high fatigue strength and durability, and are cost-effective. This category includes high-carbon spring steels, such as oil-tempered wire, hard-drawn wire, music wire, and flat cold-rolled spring steel.

Stainless Steels: Stainless steels offer remarkable mechanical properties, similar to spring steel, along with better corrosion resistance. Common stainless steel grades used in torsion springs include Grade 17-7 PH, Grade 316, Grade 304, and Grade 302.

Alloy Spring Steels: Alloy spring steels are modified with elements like: manganese, vanadium, silicon, nickel, chromium, and molybdenum to get a higher elastic limit. This makes them well-suited for demanding high-impact and shock scenarios. Examples of alloy spring steels used in torsion springs are silicon manganese, chrome silicon, and chrome vanadium.

Copper-Based Alloys: Copper-based alloys, like phosphor bronze, spring brass, beryllium copper, Monel® 400, and Monel® K 500, offer excellent corrosion resistance and electrical properties. These materials can perform well in subzero temperatures and have high ductility and strength, although they tend to be pricier than other materials.

Nickel-Based Alloys: These alloys, such as: A 286, Inconel® 600, Inconel® 718, Inconel® X-750, and Hastelloy®, provide exceptional corrosion resistance. They are also able to withstand elevated and subzero temperatures, so are commonly found in harsh environments. Nevertheless, their notable electrical resistance makes them unsuitable for use in electrical applications.

Where Can I Find Companies That Manufacture Torsion Springs?

You can use the Thomasnet Supplier Discovery Platform to find torsion spring manufacturers. Thomasnet is a comprehensive online resource tailored to assist in finding manufacturing companies and their specialized services. Start by visiting the Thomasnet website at www.thomasnet.com and initiate your search by typing “Torsion Spring Manufacturers” or relevant keywords into the search bar. After searching, you will receive a list of companies specializing in torsion spring manufacturing, complete with detailed company profiles, contact information, and descriptions of their manufacturing capabilities. Utilize the available filters, such as location and company size, to further narrow down your options. Once you’ve identified potential manufacturers, reach out to them directly through the contact details provided on their profiles.

Torsion Springs vs. Extension Springs

Torsion springs and extension springs are both helical coil springs, but they function differently. Torsion springs rotate with increasing loads and are used in applications like hinges and garage doors. Extension springs extend as loads increase and are common in scenarios in which objects need to be held tight or suspended, such as screen door springs.

In the context of garage doors, torsion springs are positioned above the door and provide balanced and even force distribution. They are known for their longevity and reliability. On the other hand, extension springs are often used in low-headroom situations and require safety cables to prevent accidents in case of spring failure.

While extension springs are cost-effective, torsion springs are more durable and offer a longer life span, making them the preferred choice for many garage-door applications. The choice between them depends on specific requirements, with torsion springs being favored for their safety, longevity, and smoother operation.

Torsion Springs vs. Leaf Springs

Torsion springs and leaf springs are two very different types of springs. Torsion springs store and release rotational energy, making them suitable for applications in which rotational force is needed, such as garage doors and mechanical systems. On the other hand, leaf springs, with their flat, layered design, are commonly used in vehicle suspensions to provide support, stability, and weight distribution, making them prevalent in trucks and heavy-duty vehicles. The choice between these two types of springs depends on the specific application, with torsion springs—excelling in confined spaces—requiring rotational force, and leaf springs offering load-bearing support and stability in automotive suspensions for heavy vehicles.