Tension springs, sometimes referred to as pull springs, are mechanical components that have hooks or loops on one or both ends of their tightly wound shape. These springs function by storing potential energy when extended, generating a force in the opposite direction as the spring’s atoms resist being moved further apart. When the applied tension is released, this elastic restoration force causes the spring to return to its original, coiled configuration.

Many industries, including manufacturing, aerospace, and transportation, use tension springs. Common applications include trampolines, industrial machinery, some garage doors, and even commonplace goods like toys. They are vital parts in many mechanical systems because they allow for controlled movement and stability by absorbing and releasing energy through tension.

This article will describe tension springs, their types, how they work, and their typical applications.

What Are Tension Springs?

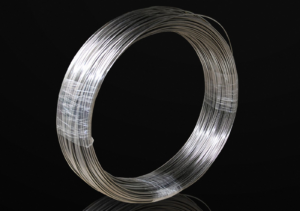

Tension springs are mechanical springs designed to undergo elastic deformation, following Hooke’s Law, when subjected to a pulling force. These springs have tightly wound coils and generally have hooks or loops for attachment on one or both ends. Their spring constant, which measures their stiffness and resistance to stretching, is a key component in the mechanics that regulate tension springs. It’s important to keep in mind, too, that excessive extension beyond their intended limitations might result in irreversible deformation and loss of functionality, emphasizing the perils of overextension. Due to its capacity to store and release mechanical energy through stress, tension springs are indispensable in a wide range of applications, including door hinges and car suspensions.

Tension Spring End Types

Tension springs are available with a number of different end types, each suited for specific applications. These are listed below:

Hand Loop and Hook at Right Angles: Ideal for easy tension adjustment and hanging applications.

Small Eye at Side: Useful for attaching to a rod or bolt.

Single Full-Loop Centered: Provides even tension distribution and stability.

Machine Half-Loop Over Center: Common in industrial machinery, offers reliable tension.

Long Square-End Hook Over Center: Used in heavy-duty applications, it ensures a secure grip.

Straight End Annealed to Allow Forming: Allows customization of end shape as needed.

Coned End with Swivel Hook: Offers flexibility and rotation, great for suspension systems.

Small Eye Over Center: Suitable for applications requiring precise alignment.

Choosing the right tension spring end type depends on the specific requirements of your application, including load, available space, and functionality.

Tension Spring Examples

Tension springs are commonly used in various applications to store mechanical potential energy by stretching. Some general situations where tension springs are most useful include:

Trampolines

Tension springs play a crucial part in trampoline design by supplying the essential elasticity and bounce to the rebound surface. Usually located along the frame, the tension springs serve to both absorb and store kinetic energy. The springs store potential energy as they extend. These tension springs unleash their accumulated energy as the jumper pushes off the trampoline surface, lifting them upward. The spring’s capacity to continually extend and retract ensures a joyful and secure jumping experience. Trampolines offer an easily understood example of how tension springs effectively collect and then release mechanical energy, making them an important part of sporting goods and exercise equipment.

Garage Doors

In most garage door systems, tension springs are used. At each end of the garage door, there is a dual-spring system in use. These springs work by storing energy in the stretching of tightly wound wire. When the garage door is closed, tension springs can stretch to nearly twice their neutral length. The coils eventually lose their tightness due to metal fatigue, though, which can happen over time.

Door Locks

Tension springs play a significant role in door locks, where security and functionality are paramount. These springs are strategically employed to ensure that when the lock is unlocked, the stop plate, against which the door handle is pressed, returns to its original position. This action creates the necessary tension, ensuring the door lock engages securely with the frame, effectively keeping the door locked. Tension springs are an excellent choice for this purpose due to their reliability, durability, and ability to withstand repeated use without deformation.

Industrial Robots

The design of mechanical arms, in particular, makes substantial use of tension springs in the field of industrial robotics. Tension springs are used to help counterbalance the robot arm’s weight, allowing for precise and controlled movements. The tension spring stores potential energy as the arm is extended, which can be effectively used to help lift, lower, or maneuver objects. Tension springs are an essential component since this dynamic balance not only conserves energy but also increases the robot’s overall effectiveness.

Upholstery

Tension springs are commonly used in upholstery to provide essential support and comfort to various types of seating. These springs, typically made of durable materials like steel, are strategically placed within the seat’s framework. They offer several advantages that make them a good choice for this purpose. Tension springs play a crucial role in ensuring weight distribution, which prevents sagging and promotes even wear over time. This vital function maintains the structural integrity of various applications such as mattresses. This contributes to the longevity of the upholstery. Secondly, tension springs offer varying levels of firmness, allowing customization based on the specific seating requirements, from plush lounge sofas to firmer dining chairs. Moreover, tension springs reduce pressure points and enhance seating comfort, making them an excellent choice for creating cozy and durable upholstered furniture.

Pliers

Pliers are one example of a tool that uses tension springs. The pliers’ hinge mechanism contains a spring, which generates tension when the handles are pressed together. The role of the spring is to make it easier to release the jaws when you press the release lever, making it easier to do activities like cutting, bending, or securely holding materials. While tension springs in vice grips enhance functionality, it’s important to note that the tool remains functional without them. The springs primarily facilitate jaw release via the release lever.

How Are Tension Springs Manufactured?

Tension springs are manufactured using modern CNC equipment. A wire is initially unspooled from its coil and then shaped using the spring winding procedure. The ends are next fashioned, and extra finishing procedures like heat treatment may come after that. To make bends and hoops, forming machines are used. Springs are heat treated after forming, sometimes just to relieve stresses built up during cold working to form the spring shape, sometimes to add to the final strength by precipitation hardening, when age-hardenable alloys are used to fabricate springs. To increase corrosion resistance and appearance, the last stage of fabrication may comprise coating and finishing procedures such as plating. Together, these manufacturing steps create tension springs of the highest caliber, customized for a variety of applications. This process is quite flexible and can be used to make compression, torsion, or tension springs.

What Are Tension Springs Made Of?

Springs are produced from a range of materials, including: stainless steel alloys (17-7PH), high-carbon steel (music wire), chrome silicon steel alloy (Cr-Si), nickel-based alloys (Inconel 600), and titanium alloys (Ti-6Al-4V). Steel, especially, is prevalent for industrial springs due to its strength, lightweight, elasticity, corrosion resistance, and superior fatigue resistance, making it ideal for long-term, cyclic load applications. These relevant characteristics of steel make it popular as a spring material. Steel tension springs can be further divided into a variety of types, such as cold-rolled steel, alloy steel, and stainless steel, each of which has unique benefits and qualities that are appropriate for a range of applications. A spring’s intended application, expected durability, corrosion resistance, and other characteristics all play a role in the material selection process.

Where Can I Find Companies That Manufacture Tension Springs?

Using the Thomasnet Supplier Discovery Platform, you can identify tension spring manufacturers with ease. With thousands of enterprises organized by their manufacturing services and goods, Thomasnet provides a comprehensive directory. With the help of this website, you can quickly locate reputable vendors to meet your spring-related requirements, ensuring you have access to a broad selection of choices and industry knowledge.

Tension Springs vs. Compression Springs

Tension springs and compression springs differ in both construction and usage. In construction, tension springs typically feature a tight coil design. They have hooks, eyes, or other end configurations to attach to objects.

Compression springs, on the other hand, are constructed to compress or shorten when force is applied, with an open coil design and no special end attachments.

Tension springs are employed to create tension or pull forces, as in garage doors or trampolines, while compression springs absorb and store energy when compressed, as in such products as mattresses. Coil springs in cars provide another example of spring applications. The basic difference in their working mechanisms is that one extends and the other compresses.